Homemade Epoxy Fly Turner

Posted: Wed Oct 03, 2012 3:56 pm

Being a "thrifty" guy, I couldn't bring myself to pay $50 up for a glorified motor. I decided to build one. That was about two years ago. I finally made one that I am not entirely happy with but it is a start. I start with a 120 VAC motor ($1 ebay $6 ship), a piece of oak (Home Depot $6) to hold it up, and a foam disk (free packing material from work).

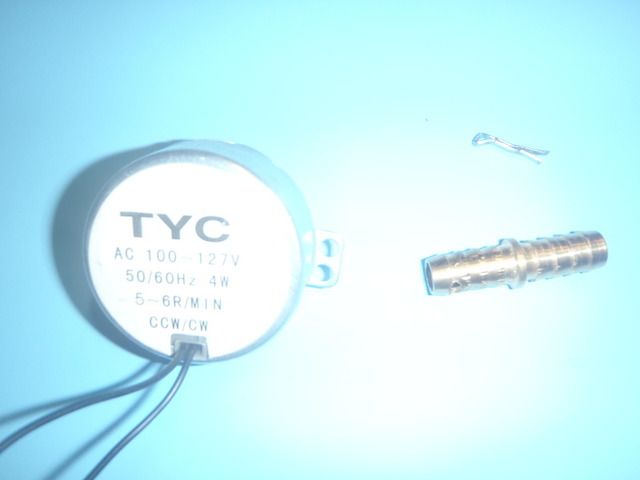

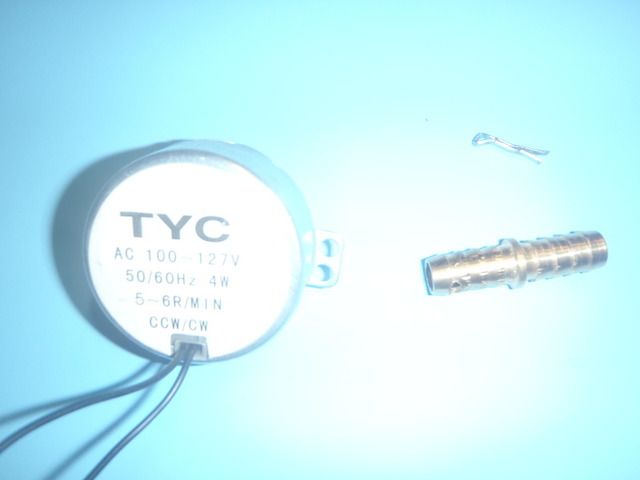

Here is the motor.

I added a switch, a fuse holder, some old wire and solder, half of an old BUD box, and a cheap electric extension cord (cord from Ace $2 - the rest was crap I had in the garage).

Then when the motor arrived I took it Home Depot to find something to hook up the shaft of the motor (apparently metric) to my foam disk. I ended up with a hose barb connector, a screw, and some washers.

Motor with hose barb drilled and cotter pinned. On the other end I just used the screw to cut it own threads through the brass and then the screw is removed. The washers fit over the barb but wedge at the center divider. The foam disk is slid over next followed by more washers and the screw.

I chopped up the oak, glued some thing with Gorilla Glue, and came up with the following parts.

These parts when dry fitted looked something like this.

I used some stain / urethane crap to seal everything and realized that I suck at that. I soldered the switch, motor, fuse holder, and extension cord together.

The "finished" project ended up looking like this.

I alos decided to start some big flies after watching the Lousiana fly fishing pron Jeff posted. I started with foam "people" starters from Hobby Lobby and then hacked at them with scissors to shape. Those are still a work in progress. These people starters are on the lower left in the photos.

A few notes for those that might try this.

CW/CCW for an AC motor means the motor will decide to turn one way or the other at random on start up - so a SPST switch is fine. The motor will have a slight burn in time where it may randomly change direction for no reason but that seems to go away after an hour of run time.

The foam wheel hose barb has a little slop - This is a better solution but is it worth it?

No real need to make a fancy stand bacause in the end the stain job will get rushed and disappoint you.

In the end, I have a perfectly functional turner based on a $1 with $6 shipping motor.

Here is the motor.

I added a switch, a fuse holder, some old wire and solder, half of an old BUD box, and a cheap electric extension cord (cord from Ace $2 - the rest was crap I had in the garage).

Then when the motor arrived I took it Home Depot to find something to hook up the shaft of the motor (apparently metric) to my foam disk. I ended up with a hose barb connector, a screw, and some washers.

Motor with hose barb drilled and cotter pinned. On the other end I just used the screw to cut it own threads through the brass and then the screw is removed. The washers fit over the barb but wedge at the center divider. The foam disk is slid over next followed by more washers and the screw.

I chopped up the oak, glued some thing with Gorilla Glue, and came up with the following parts.

These parts when dry fitted looked something like this.

I used some stain / urethane crap to seal everything and realized that I suck at that. I soldered the switch, motor, fuse holder, and extension cord together.

The "finished" project ended up looking like this.

I alos decided to start some big flies after watching the Lousiana fly fishing pron Jeff posted. I started with foam "people" starters from Hobby Lobby and then hacked at them with scissors to shape. Those are still a work in progress. These people starters are on the lower left in the photos.

A few notes for those that might try this.

CW/CCW for an AC motor means the motor will decide to turn one way or the other at random on start up - so a SPST switch is fine. The motor will have a slight burn in time where it may randomly change direction for no reason but that seems to go away after an hour of run time.

The foam wheel hose barb has a little slop - This is a better solution but is it worth it?

No real need to make a fancy stand bacause in the end the stain job will get rushed and disappoint you.

In the end, I have a perfectly functional turner based on a $1 with $6 shipping motor.